Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

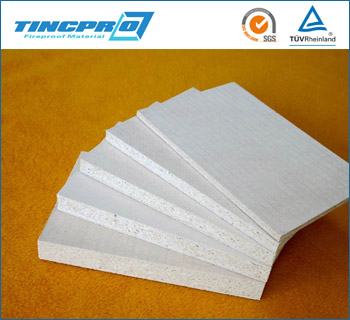

MGO Board

Magnesium oxide board is a smooth finished interior wall-lining that can be painted, wallpapered, or tiled to create or complement a wide range of design looks.

- Description

- Production line

- Installtion

- Application

- Certificate

- Package

Magnesium oxide board is a smooth finished interior wall-lining that can be painted, wallpapered, or tiled to create or complement a wide range of design looks.

Because it's fire, water and impact resistant it is particularly suitable for use in many areas within the building. Magnesium oxide board lining has recessed edges for flush jointing, creating a smooth, continuous wall surface.

Features:

1) Fireproof and Waterproof

2) Light weight and High intensity

3) Sound insulation and Heat insulation

4) Heat preservation

5) Impact resistance

6) Cold resistance

7) Flexibility

8) Mothproof and anti-mildew

9) Environmental friendly

10) Easy to construction, maintenance

Technical data:

|

Non-flammability

|

Grade A GB8624

|

|

Swelling rate

|

0.34% GA160-1997

|

|

Heating contraction

|

1.2% GA160-1997

|

|

Water resistance

|

CNS13778 no condensation on the opposite side

|

|

Impact resistance

|

CNS13788 does not crack or break

|

|

Density

|

0.95g/cm3 GB/T7019-1997

|

|

Dry bending resistance

|

16Mpa GB/T7019-1997

|

|

Wet bending resistance

|

22Mpa GB/T7019-1997

|

|

Sound insulation

|

≥44 dB (GBJ121-88)

|

|

Heat-transfer coefficient

|

0.14w/mk (GB/T 13475-92)

|

|

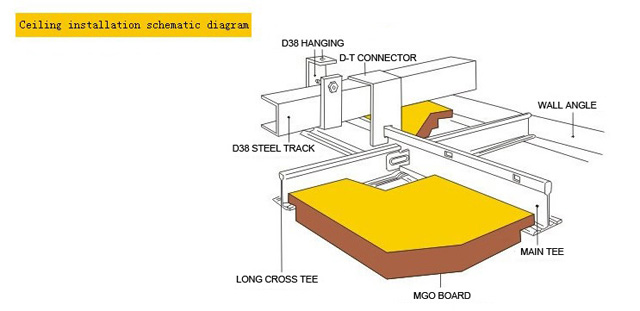

Installation

|

Easy to cut, saw, nail, stick, paint and veneer

|

|

Environmental friendly

|

Free of asbestos, formaldehyde and ammonia

|

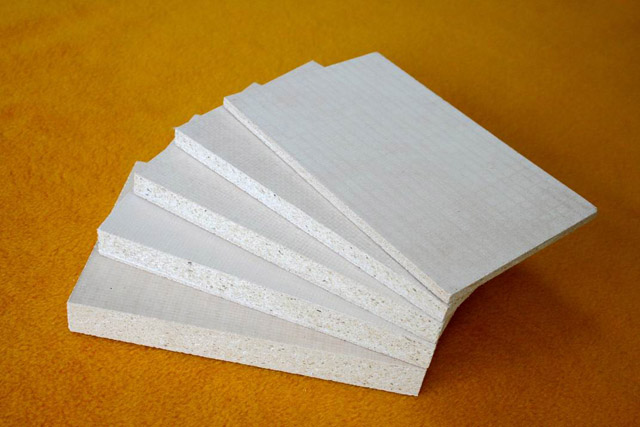

Specifications:

|

Size |

4'*8', 4'*9', 4'*10', others optional |

|

Thickness |

3-12mm standard, others optional |

|

Largest width |

1220mm |

|

Maximum length |

3050mm |

|

Color |

white/grey |

Cutting

Magnesium oxide board sheets can be cut very easily with a carbide tip knife.

For rough cuts, place the Magnesium oxide board sheet rough side up, scour along a straight line with the knife, then snap along the scoured line.

Pass the knife again along the other side to separate the two sheets to get a clean cut.

Finer cuts are achieved by using power tools such as circular saw, jigsaw, bench top saw, etc. (Please note the section of Health and Safety Practices regarding dust)

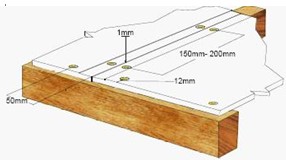

Installing

Magnesium oxide board may be fixed to either light or heavy gauge domestic type steel frames, timber frames or timber battens over masonry. All the framing and substrate used must comply with relevant building regulations and standards.

It is also important to ensure that the frame is square and straight to provide the flush face to receive the sheeting.

General

Boards should be installed individually. They should be lifted off the floor and kept

away from the ceiling by approximately 6mm to allow for any frame movement /

shrinking / expansion.

Magnesium oxide board may be screwed or nailed to the frame as appropriatly.

When using self embedding screws ensure that they do not go more than 0.5mm below the surface of the board, kept no less than 12mm away from the sheet edges, and 50mm away from the corners of the board.

Furthermore, ensure that screws do not over-spin, thus lose grip of the frame.

Jointing

For straight joints, align the recessed ends together, making sure that the joints are dry, clean and free from grease, oils or any other materials.

Embed the appropriate jointing tape (50mm wide paper or fibre mesh jointing tape) in a fine layer of jointing compound. Add another layer of jointing compound to the desired finish, wiping off any excess materials.

Both recessed edge and butt joints require joint setting by using jointing products.

The performance of every wall joint is the responsibility of its installer, as this is governed by the standard of workmanship and installation practices.

There are several factors that may affect the joint performance, such as framing quality, movement and vibrations, moisture, humidity, temperature, etc. These factors must be carefully understood and considered by the installer when selecting jointing compounds, by ensuring that the product selected has the physical attributes required to perform these considering factors. For corner joints, use a suitable corner reinforcement product, and finish off with appropriate jointing compounds.

If working conditions are hot and dry, dampen the area around the joint prior to working.

Note*

Jointing compound can also be used to cover fastener heads and any other

imperfections. Feather out towards the outside, allow to fully dry before sanding.

Finishing

Magnesium oxide board can be finished in a variety of ways including Paint, Plaster, Wallpaper, Tile or as required.

Notes*

1-For wet areas, the waterproofing requirements of all relevant codes, standards and regulations must be met.

2-Water proofing membranes manufacturers specifications and application methods must be consulted and complied with.

Glancing Light

In some instances, joints may be visible due to glancing light. To eliminate this effect, consider the following:

1-Alter the light source.

2-Work closely with the builder or designer to minimise this.

3-Ensure the joints are set in a professional tradesman-like way.

Painting

Depending on the type of paint used, sanding is recommended prior to the application of paint. It is also important to ensure that all surfaces are clean, dry and free from any dust or sanding residue.

Brand named paints usually give better results. Always follow the paint manufacturer recommendations for paint suitability, mixing instructions, and application.

Note*

Use of a 'Sealer Coat' or 'Preparation Undercoat' is recommended. Also ensure that any imperfections are cured or dealt with before the application of paint.

For expert opinions from paint manufacturers, please download the recommendations on painting Magnesium oxide board from Dulux and Resene.

Tiling

Magnesium oxide board is considered as one of the best products on the market for tiling.

It is recommended that only flexible tile adhesive be used for tile applications. Please refer to adhesive manufacturer for suitability and application information.

It is also important to note that the weight loading of the tiles depends on the

thickness of the Magnesium oxide board used, and also on stud centres.

Support angles are necessary to transfer the weight of the tiles onto the framing,

where a structural engineer is to determine their suitability and positioning.

Support angles need to be fixed onto the supporting frame, and the overall wall mass and stability needs to be considered.

Maintenance

It is recommended that all the cleaning and maintenance of the finishing be carried out regularly and in strict accordance with its manufacturer. Joints must also be maintained and kept free of dirt and grime.

|

规格

|

20尺柜

|

|

|

长×宽×厚(毫米)

|

托装

|

散装

|

|

2500×900×3mm

|

300*8=2400

|

2600

|

|

2700×900×3mm

|

300*8=2400

|

2500

|

|

3000*900*3mm

|

300*4=1200

|

|

|

2400×900×3mm

|

300*8=2400

|

|

|

2400×1200×3mm

|

300*6=1800

|

2200

|

|

2280*1200*3mm

|

300*8=2400

|

|

|

2500*1200*3mm

|

300*6=1800

|

|

|

2700*1200*3mm

|

300*6=1800

|

|

|

3000*1200*3mm

|

300*3=900

|

|

|

|

|

|

|

2500×900×4mm

|

225*8=1800

|

|

|

2700×900×4mm

|

225*8=1800

|

|

|

3000*900*4mm

|

225*4=900

|

|

|

2400×900×4mm

|

225*8=1800

|

|

|

2400×1200×4mm

|

225*6=1350

|

2000

|

|

2280*1200*4mm

|

225*8=1800

|

|

|

2500*1200*4mm

|

225*6=1350

|

|

|

2700*1200*4mm

|

225*6=1350

|

|

|

3000*1200*4mm

|

225*3=675

|

|

|

|

|

|

|

2500×900×5mm

|

180*8=1440

|

|

|

2700×900×5mm

|

180*8=1440

|

|

|

3000*900*5mm

|

180*4=720

|

|

|

2400×900×5mm

|

180*8=1440

|

|

|

2400×1200×5mm

|

180*6=1080

|

1600

|

|

2280*1200*5mm

|

180*8=1440

|

|

|

2500*1200*5mm

|

180*6=1080

|

|

|

2700*1200*5mm

|

180*6=1080

|

|

|

3000*1200*5mm

|

180*3=540

|

|

|

|

|

|

|

2500×900×6mm

|

150*8=1200

|

|

|

2700×900×6mm

|

150*8=1200

|

|

|

3000*900*6mm

|

150*4=600

|

|

|

2400×900×6mm

|

150*8=1200

|

|

|

2400×1200×6mm

|

150*6=900

|

1330

|

|

2280*1200*6mm

|

150*8=1200

|

1300

|

|

2500*1200*6mm

|

150*6=900

|

|

|

2700*1200*6mm

|

150*6=900

|

|

|

3000*1200*6mm

|

150*3=450

|

|

|

规格

|

20尺柜

|

|

|

长×宽×厚(毫米)

|

托装

|

散装

|

|

2500×900×8mm

|

115*8=920

|

|

|

2700×900×8mm

|

115*8=920

|

|

|

3000*900*8mm

|

115*4=460

|

|

|

2400×900×8mm

|

115*8=920

|

|

|

2400×1200×8mm

|

110*6=660

|

1000

|

|

2280*1200*8mm

|

115*8=920

|

930

|

|

2500*1200*8mm

|

115*6=690

|

|

|

2700*1200*8mm

|

115*6=690

|

|

|

3000*1200*8mm

|

115*3=345

|

|

|

|

|

|

|

2500×900×9mm

|

100*8=800

|

|

|

2700×900×9mm

|

100*8=800

|

|

|

3000*900*9mm

|

100*4=400

|

|

|

2400×900×9mm

|

100*8=800

|

|

|

2400×1200×9mm

|

100*6=600

|

880

|

|

2280*1200*9mm

|

100*8=800

|

|

|

2500*1200*9mm

|

100*6=600

|

|

|

2500*1200*9mm

|

|

|

|

2700*1200*9mm

|

100*6=600

|

|

|

3000*1200*9mm

|

100*3=300

|

|

|

|

|

|

|

2500×900×10mm

|

90*8=720

|

|

|

2700×900×10mm

|

90*8=720

|

|

|

3000*900*10mm

|

90*4=360

|

|

|

2400×900×10mm

|

90*8=720

|

|

|

2400×1200×10mm

|

90*6=540

|

800

|

|

2280*1200*10mm

|

90*8=720

|

720

|

|

2500*1200*10mm

|

90*6=540

|

|

|

2700*1200*10mm

|

90*6=540

|

|

|

3000*1200*10mm

|

90*3=270

|

|

|

|

|

|

|

2500×900×12mm

|

75*8=600

|

|

|

2700×900×12mm

|

75*8=600

|

|

|

3000*900*12mm

|

75*4=300

|

|

|

2400×900×12mm

|

75*8=600

|

|

|

2400×1200×12mm

|

75*6=450

|

630

|

|

2280*1200*12mm

|

75*8=600

|

|

|

2500*1200*12mm

|

75*6=450

|

|

|

2700*1200*12mm

|

75*6=450

|

|

|

3000*1200*12mm

|

75*3=225

|

|

|

规格

|

20尺柜

|

|

|

长×宽×厚(毫米)

|

托装

|

散装

|

|

2500*900*15mm

|

60*8=480

|

|

|

2400*900*15mm

|

60*8=480

|

|

|

2700*900*15mm

|

60*8=480

|

|

|

3000*900*15mm

|

60*4=240

|

|

|

2440×1220×15mm

|

60*6=360

|

|

|

2280*1200*15mm

|

60*8=480

|

|

|

2500*1200*15mm

|

60*6=360

|

|

|

2700*1200*15mm

|

60*6=360

|

|

|

3000*1200*15mm

|

60*3=180

|

|

|

|

|

|

|

2400*900*18mm

|

50*8=400

|

|

|

2700*900*18mm

|

50*8=400

|

|

|

3000*900*18mm

|

50*4=200

|

|

|

2440*1220*18mm

|

50*6=300

|

450

|

|

2700*1200*18mm

|

50*6=300

|

|

|

3000*1200*18mm

|

50*3=150

|

|

|

|

|

|

|

1830*915*20mm

|

48*12=576

|

|

|

2400*900*20mm

|

45*8=360

|

|

|

2700*900*20mm

|

45*8=360

|

|

|

3000*900*20mm

|

45*4=180

|

|

|

2440×1220×20mm

|

45*6=270

|

|

|

2700×1200×20mm

|

45*6=270

|

|

|

3000×1200×20mm

|

45*3=135

|

|

|

Specification

|

Loading quantity (PCS/20GP) loose packing

|

Loading quantity (PCS/20GP) packing in pallet

|

|

1220*2440*3

|

2600

|

300*6=1800

|

|

1220*2440*4

|

2000

|

225*6=1350

|

|

1220*2440*5

|

1600

|

180*6=1080

|

|

1220*2440*6

|

1300

|

150*6=900

|

|

1220*2440*8

|

1000

|

110*6=660

|

|

1220*2440*10

|

800

|

90*6=540

|

|

1220*2440*12

|

650

|

75*6=450

|

|

1220*2440*15

|

530

|

60*6=360

|

|

1220*2440*18

|

440

|

50*6=300

|

|

1220*2440*20

|

400

|

45*6=270

|

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation